PRODUCTS

|

|

GKF Clean Horizontal Scraper Fully Automatic Centrifuge

Collect

Product Description

The GKF explosion-proof horizontal scraper discharge centrifuge is a continuous operation and gap operation filter centrifuge. The structure and system design fully consider the GMP requirements in the pharmaceutical industry, and is suitable for pharmaceutical and explosion-proof requirements. The wall mounted installation form completely isolates the working area from the machine base, transmission, and hydraulic devices. The independent hydraulic system and lubrication system are equipped with nitrogen protection system (optional), online cleaning system (optional), gas back blowing (optional), PLC program control, frequency converter speed regulation, and resistance energy consumption braking. Its control method is automatic control (or manual control is also possible). The feeding, separation, washing, dehydration, unloading, filter cloth regeneration, online cleaning, nitrogen protection, and other processes during the operation of the centrifuge are operated according to pre-set programs. The single cycle time is short, the processing capacity is large, and good filtration (low moisture content of filter cake) and washing effect can be achieved. GKF explosion-proof horizontal scraper discharge centrifuge is suitable for solid-liquid separation of low viscosity, toxic, harmful, flammable, and explosive media. Mainly used for solid-liquid separation in industries such as pharmaceuticals and food. Main features: 1. Using PLC and touch screen control, it automatically runs according to the predetermined program, achieving human-machine dialogue and convenient operation and maintenance. 2. The action components adopt electrical hydraulic automatic control. Monitor the entire process of cleaning, feeding, initial filtration, washing, fine filtration, unloading, gas backflushing, and batch cleaning before feeding. 3. Independent electrical control box for remote control. 4. Safety protection: speed detection, over vibration protection, cover opening protection, motor overload and overheating protection, scraper rotating mechanical and electrical dual protection. 5. The rack adopts a fully welded structure, with a compact structure and high machine bearing strength. Wall mounted design, with transmission, base, motor, and hydraulic systems installed in non clean areas. The drum and casing are located in the clean area, and the rack panel is flexibly connected to the wall to isolate the clean area from the non clean area. 6. The casing is in the form of a large flip cover, which facilitates complete cleaning of the drum; Quick opening hydraulic locking structure, easy to operate. 7. The motor and centrifuge host are installed as a whole, which is convenient for users to install and use, and reduces the space occupied by the machine. 8. Fully enclosed structure, with sealing components made of silicone rubber or fluororubber. 9. Adopting variable frequency control, the drum speed is infinitely adjustable. The speed of feeding, washing, separation, unloading, and residual filter cake blowing can be set according to the process requirements. 10. Design vibration isolation devices and rubber vibration reduction foundations to ensure smooth machine operation, greatly reduce vibration and noise, improve production workshops and working environments, and reduce the harm of machine vibration to equipment and the environment. 11. The material in contact between the centrifuge and the separation medium is made of stainless steel, which improves the corrosion resistance and hygiene requirements of the machine. 12. Equipped with a gas blowback device (optional), it can assist the scraper in scraping materials and reduce residual filter cake layers. 13. Configure an online cleaning system (optional), with multiple cleaning heads installed inside the centrifuge, such as the outer surface of the drum, discharge hopper, sight glass, and bottom of the drum, for online (in place) flushing to meet process cleanliness requirements. 14. Configure a nitrogen protection system (optional), inject nitrogen into the centrifuge working area, and the control system automatically controls the nitrogen concentration/pressure to meet explosion-proof requirements. Product parameters

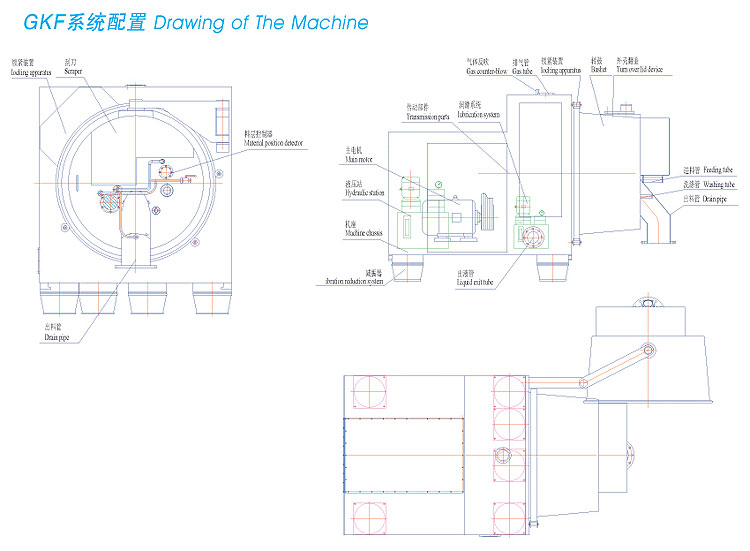

Product structure:

Product parameters:

|