PRODUCTS

|

|

PSD belt flat upper discharge centrifuge

Collect

Product Description

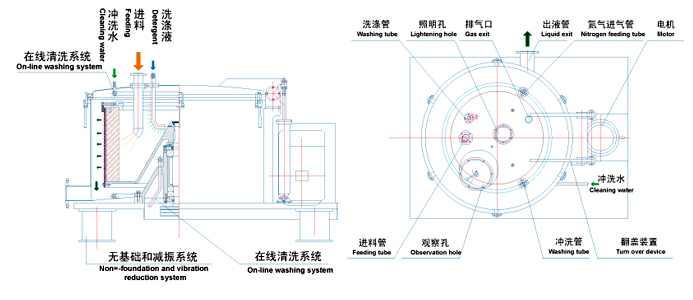

Main features: 1. Adopting variable frequency control, the startup is stable, and the separation factor is adjustable. 2. Bag unloading with low labor intensity and high work efficiency. 3. The structural design is reasonable and effectively eliminates sanitary dead corners. The transition of the structural components is smooth, and the surface is polished. The external structural components, fasteners, and drum are all made of stainless steel. The shell is a flip type, which can thoroughly clean the space between the centrifuge shell and the drum interlayer. 4. The base and casing are welded together as a whole, with high load-bearing strength. 5. The base is a flat structure, which reduces the center of gravity of the machine and provides smaller installation space. The flat base can also serve as an operating platform, making operation more convenient. 6. Equipped with liquid damping dampers, it effectively eliminates vibration and simplifies daily maintenance. 7. The outer shell is flipped over, equipped with feeding pipes, washing pipes, observation glasses, and lighting holes. 8. Equipped with an online cleaning system, it can clean the invisible parts inside the centrifuge, such as the inner wall of the centrifuge casing, the inner and outer surfaces of the drum, and the surface of the collection tank, ensuring cleanliness requirements and complying with GMP standards. 9. Simple structure, convenient operation and maintenance. 10. The grains are not easily broken. 11. Configure a nitrogen protection system to ensure the isolation of the centrifuge chamber from the external air. 12. Strong universality and wide applicability. 13. Sealed structure, sealing components made of silicone rubber or fluororubber. It can meet the requirements of enclosed explosion-proof and is suitable for applications in toxic, flammable and explosive environments. The above configurations can be divided into chemical and pharmaceutical use, and can be selected according to specific requirements to meet technical and economic requirements. Standard configuration: ◆ Structure: The shell is equipped with a flip cover, feed pipe, washing pipe, observation mirror, exhaust port, and lighting hole; The enclosed structure, drum, casing, flip cover and other components are made of stainless steel material (SUS304). ◆ All fasteners are made of stainless steel. ◆ Transmission and braking: ordinary motor (or explosion-proof motor)+frequency converter+energy consumption braking. ◆ Electric control device (control box) ◆ Liquid damping damper. ◆ When the machine leaves the factory, it is equipped with one set of dedicated lifting tools. Optional configuration: ◆ Online cleaning system. ◆ Nitrogen protection system. ◆ According to the anti-corrosion requirements of the materials separated by the user, corresponding stainless steel materials (SUS304, 316, 316L, 321, etc.) or titanium materials (TA) should be used. ◆ Overvibration protection device. ◆ Open cover protection device. ◆ On site explosion-proof button. Product parameters

Product structure:

Product parameters:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||