PRODUCTS

|

|

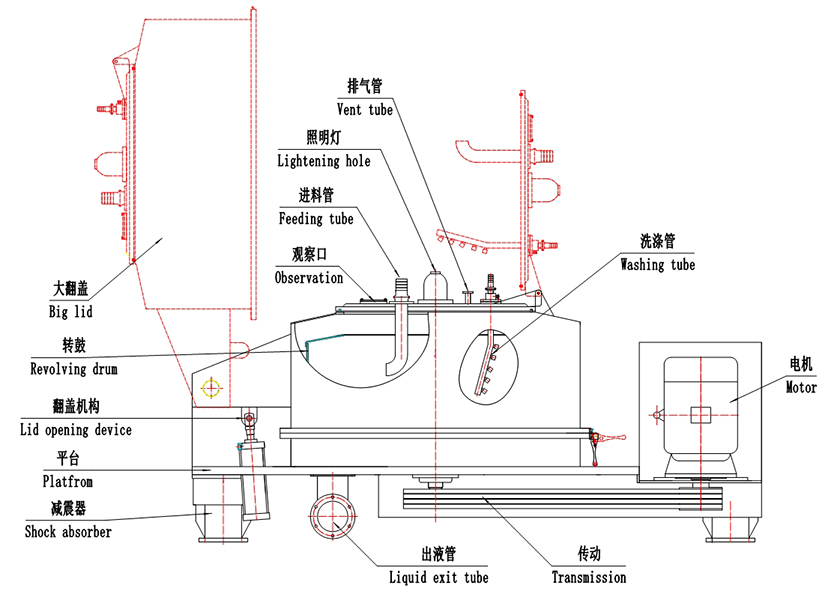

PQSB fully flipped flat plate upper discharge centrifuge

Collect

Product Description

Working principle: The material to be separated enters the high-speed rotating centrifuge drum through the feed pipe. Under the action of the centrifugal force field, the material is filtered through a filter cloth (filter), and the liquid phase is discharged through the outlet pipe. The solid phase is retained in the drum. When the filter cake in the drum reaches the specified loading amount of the machine, stop feeding, wash the filter cake, and filter out the washing solution. After the filter cake meets the requirements for liquid removal, stop the machine and manually unload the filter cake. Enter standby mode. Main features: 1. The fully flipped structure has a smooth transition of structural components, and the surface has been polished to effectively eliminate hygiene dead corners. The external structural components, fasteners, and drum are made of stainless steel, which can thoroughly clean the centrifuge casing, drum, and outlet tank. 2. The machine base is a flat structure, with a low center of gravity, small footprint, and convenient operation. 3. The liquid damping configuration has good vibration reduction effect and simplifies daily maintenance. 4. Install feeding pipes, washing pipes, observation glasses, and lighting holes on the flip cover. Configure an online cleaning system (optional) to clean the inner walls of the centrifuge casing, the inner and outer surfaces of the drum, and the surface of the collection tank, ensuring cleanliness requirements and compliance with GMP standards. 5. Strong versatility, less prone to grain breakage, suitable for both solid phase suspension separation and fiber like material separation, with a wide range of applications. 6. Using a frequency converter for smooth start-up and adjustable separation factor; Equipped with a nitrogen protection system (optional), it can achieve explosion-proof requirements for enclosed structures and is suitable for applications in toxic and flammable environments. Product parameters

Product structure:

Product parameters:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||