PRODUCTS

|

|

LGZ Vertical Scraper Lower Discharge Fully Automatic Centrifuge

Collect

Product Description

Main features: 1. Flat plate structure and liquid damping vibration reduction technology: By using a flat plate structure, the center of gravity of the machine is lower and the operation is smoother. The flat plate serves as both a base and an operating platform, making operation more convenient; The application of liquid damping technology makes the isolation and vibration reduction performance of centrifuges more superior; Adopting a four point support structure, with a large support distance and no foundation installation form, it is convenient for machine installation and maintenance. 2. Independent inclined plate feeding device: Drawing on advanced foreign technology, it has significantly improved the uniformity and operability of feeding by breaking away from traditional intermediate or lateral feeding methods. It can also be connected to the electrical control system to achieve automatic control. 3. Gas recoil and gas assisted scraper device: The application of this new technology can minimize the residual filter cake and facilitate the regeneration of the filter cloth. 4. Nitrogen protection system: Adopting nitrogen protection to ensure the machine operates in a safe environment. 5. Large flap structure and online cleaning device: In accordance with GMP specifications, the upper cover of the centrifuge is designed as a large flap structure, making maintenance and filter cloth installation more convenient; Setting up a cleaning device in the centrifuge chamber can perform online cleaning of the centrifuge chamber during operation and preparation according to process requirements, effectively eliminating contamination between batches. 6. Humanized design: No basic structure, spacious operating platform, lightweight flip device, automatic online cleaning device, explosion-proof light setting, observation mirror and mirror cleaning device, various warning and warning signs, etc. make use and maintenance simpler and more convenient, fully reflecting the humanized design concept contained in the design. 7. Safety protection device: The concept of "safety is paramount" is fully reflected in the design and manufacturing process. Whether it is strength calculation, life verification, or the setting of safety devices, this principle is fully reflected. A series of mechanical and electrical interlocking protection devices are set up, such as over vibration protection, over current protection, temperature control protection, material layer control, scraper stroke protection, and cover opening protection, to ensure that the machine is always in a safe state during use. 8. Automated human-machine interface control: Through PLC, touch screen, frequency converter control, energy consumption braking, pneumatic or hydraulic systems, the machine can design corresponding work programs according to process requirements and automatically run according to the set programs. Advanced application programs are used to make it more convenient to modify programs, and the interface is also more user-friendly. Through the network, remote control can be achieved, truly achieving on-site unmanned operation and meeting the requirements of modern large-scale production for equipment. The designed equipment fault self diagnosis system can more conveniently and quickly solve faults that occur during operation. 9. Pneumatic form: Adopting pneumatic form, automatic action components adopt pneumatic system, clean and hygienic. Effectively avoiding oil leakage and material pollution, meeting the cleanliness requirements in pharmaceuticals, food, and fine chemicals. 10. Surface treatment technology: Adopting corresponding processing techniques, polishing, sanding, pickling, passivation and other processes are carried out on the surface of the workpiece. Corresponding measures are taken for welds, inner holes, threads, fastening structures, etc. to ensure that the surface condition meets the relevant requirements of GMP specifications. Standard configuration: ◆ Structure: The shell is equipped with a flip cover, feed pipe, washing pipe, observation mirror, exhaust port, and lighting hole; The enclosed structure, drum, casing, flip cover and other components are made of stainless steel material (SUS304). The base and other components are cast parts, with stainless steel lining on the surface. The surface of the drum, the inner and outer surfaces of the casing, and the exposed parts of the machine are all polished. ◆ All fasteners are made of stainless steel. ◆ Using PLC control. ◆ Electromechanical material control. ◆ Independent inclined plate fabric device. ◆ Transmission and braking: ordinary motor (or explosion-proof motor)+frequency converter+energy consumption braking. ◆ Pneumatic system. ◆ No foundation form (balance block+imported high-precision liquid damping damper). Optional configuration: ◆ Online cleaning system. ◆ Nitrogen protection system. ◆ Touch screen control. ◆ Hydraulic action system. ◆ Gas assisted scraper. ◆ Lateral fabric device. ◆ According to the anti-corrosion requirements of the materials separated by the user, corresponding materials (SUS304, 316, 316L, 321, etc.) or titanium materials (TA) should be used, or the surface should be lined with PE, HALAR, etc. ◆ Overvibration protection device. ◆ Open cover protection device. ◆ On site explosion-proof button. ◆ Transmission and braking: explosion-proof motor+frequency converter+energy consumption braking. Product parameters

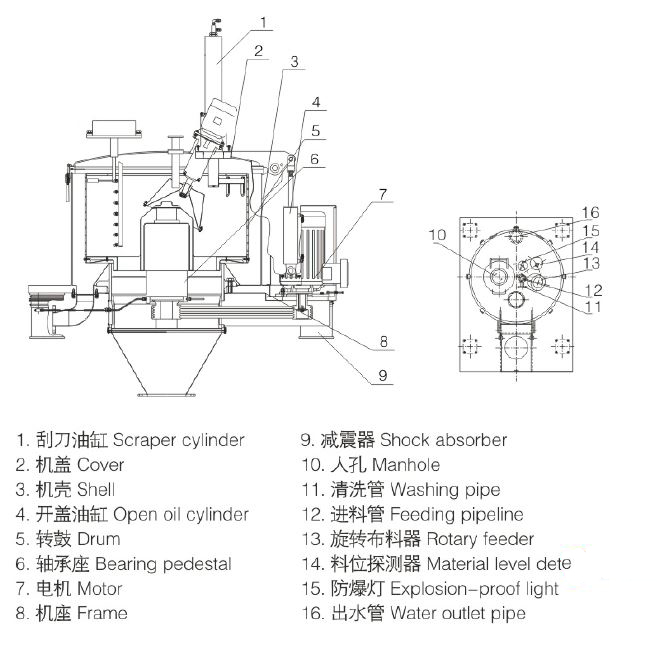

Product structure:

Product parameters:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||