PRODUCTS

|

|

LLW hydraulic horizontal filtering spiral discharge centrifuge

Collect

Product Description

Working principle: 1.The LLW horizontal spiral discharge filter centrifuge is a model with low energy consumption, stable performance, and good separation effect. The feeding, dehydration, washing, unloading and other processes in the separation process are continuously completed, with high production efficiency and automation, making it an advanced solid-liquid separation equipment. 2.The suspension enters the spiral cavity from the feed pipe and enters the drum through the nozzle near the bottom of the cone end through the small head of the spiral. Under the action of the centrifugal force field, the liquid phase in the slurry is filtered out through the sieve laid on the rotating wall, and the solid particles are intercepted in the drum; At the same time, the solid particles inside the drum move from the small end of the drum to the large end of the drum under the centrifugal force and the relative differential speed between the spiral and the drum. 3.During this movement, due to the increase in the rotation diameter, the centrifugal force increases rapidly. The solid phase reaches the minimum moisture content from the initial high moisture content when entering to the lowest moisture content when discharged from the drum, thus achieving automatic and continuous separation of the solid and liquid phases. 4.The centrifuge is equipped with a built-in washing tube, which can wash the filter cake while filtering it. Due to the thin layer filter cake washing, the washing effect is good and the consumption of washing solution is low. 5.A steam pipe can be designed on the back of the drum to perform high-temperature washing on the crystallized material on the back of the drum. 6.Spiral differential has three configurations: cycloidal differential, planetary differential, and hydraulic differential, which meet the separation of different materials. Main use: The LLW horizontal spiral discharge filter centrifuge is widely used in industries such as chemical, food, salt, mining, and pharmaceuticals. Due to its separation principle and structural characteristics, it has strong specificity for materials and is mainly suitable for materials with large particle size and no strict requirements for particle crushing. Material analysis and corresponding tests should be conducted during selection to determine its applicability and separation performance. We have over 80 types of material application data and successful experience, and can communicate with our technical personnel during selection to obtain more detailed information. Product parameters

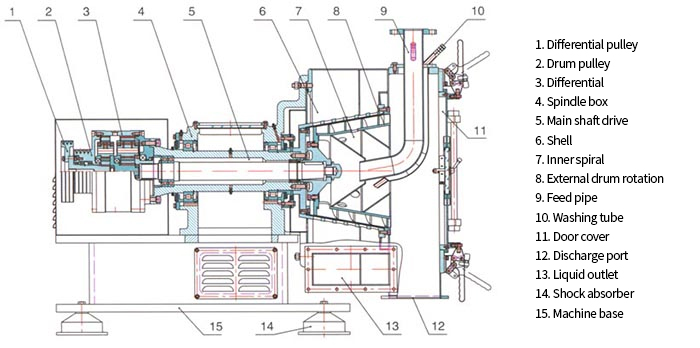

Product structure:

Product parameters:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||