PRODUCTS

|

|

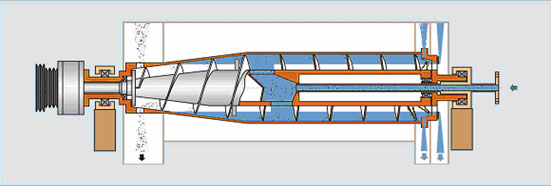

LW three-phase separation horizontal settling spiral discharge centrifuge

Collect

Product Description

Working principle: The structure of a three-phase centrifuge mainly consists of differential, screw, drum, cover, base, lubrication system, motor, and other parts. The working principle is that the suspension enters the drum through the feed pipe and spiral discharge port. Under the centrifugal force generated by high-speed rotation, solid-phase particles with higher density deposit on the inner wall of the drum. The spiral blades that move relative to the drum continuously scrape the solid-phase particles deposited on the inner wall of the drum and push them out of the slag discharge port. Liquid phases with different densities form two liquid rings inside the drum and flow out through two different outlets of the large end cover. The relative motion between the spiral and the drum is achieved by a differential, with the outer shell of the differential connected to the drum and the output shaft connected to the spiral. The main motor drives the drum to rotate, while the auxiliary motor drives the input shaft of the differential to rotate. The output shaft transmits torque to the screw at a certain speed ratio, achieving the continuous separation process of materials by the centrifuge. Structural features: 1. Widely used: suitable for solid-liquid three-phase separation in industries such as chemical, light industry, food, kitchen waste, sludge, and environmental protection. For example, the separation of oil-water residue in vegetable oil, oil in fish meal, hydrolyzed protein, residue, and oil-water residue in oil fields; 2. High degree of automation: The feeding, separation, unloading and other processes of this machine are continuously and automatically completed under full speed operation; 3. Adjustable differential speed: This machine adopts dual frequency conversion control, which can adjust the differential speed within a certain range to achieve the best effect; 4. Clean and pollution-free: The separation of materials by this machine is carried out in a completely enclosed environment, which does not pollute the site and ensures the cleanliness and hygiene of the production environment. 5. Good operational stability: This machine adopts a cycloidal differential, which is reliable in performance and operates at low temperatures. 6. Strong corrosion resistance: The material in contact with the material in this centrifuge is all stainless steel, which has strong corrosion resistance. 7. Simple operation and precise adjustment: This machine adopts advanced international technology, and the light phase baffle and heavy phase baffle can be adjusted and replaced without opening the drum. The baffle is precisely adjusted, with no change in position, simple adjustment, and easy operation. Product parameters

Product structure:

Product parameters:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||