PRODUCTS

|

|

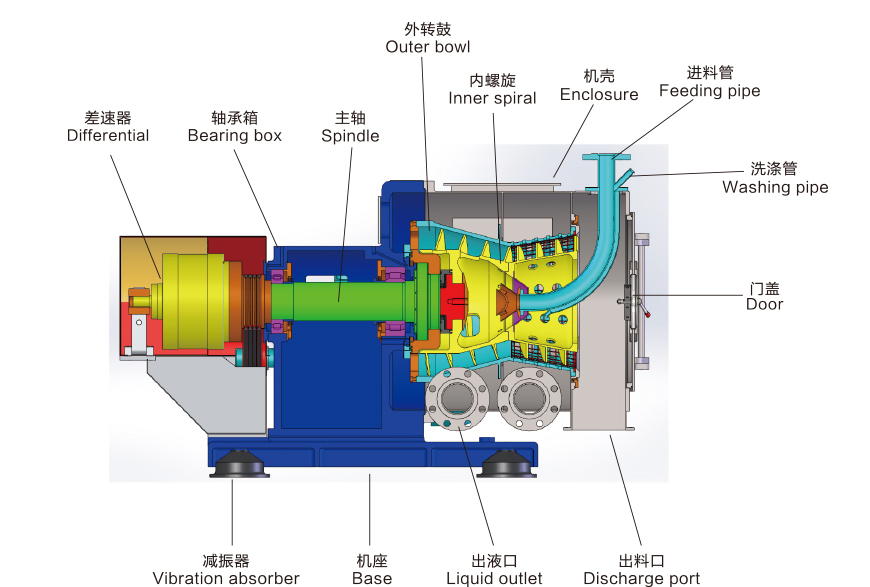

LLWZ settling filter spiral discharge centrifuge

Collect

Product Description

Product features: The LLWZ horizontal spiral concentration filtration combination centrifuge first enters the settling drum, and through the settling principle, the material is first settled and concentrated before entering the filtering drum for filtration, separation, and washing. The suspension enters the settling drum through the feed pipe and enters from the large end of the drum. Under the action of centrifugal force, the solid phase in the slurry settles on the drum wall and moves towards the small end under the action of the screw. The liquid phase is discharged through the overflow hole at the large end of the drum, and the filter cake is pressed and dehydrated during the movement towards the small end before entering the filtering drum. The solid phase moves from the small end of the drum to the large end under the action of centrifugal force and the differential speed between the screw and the drum. As the rotary diameter of the drum increases, the centrifugal force also increases, and the intercepted solid phase reaches the minimum moisture content when discharged from the drum, achieving automatic and continuous separation of solid-liquid phases. Configure a washing tube to wash and purify the filter cake in the later stage of filtration. A thinner filter layer can achieve better washing results and lower detergent consumption. For materials that are prone to secondary crystallization, steam pipes can be configured to perform high-temperature cleaning of the crystallization in the inner cavity according to the set cleaning cycle. The LLWZ horizontal spiral concentration filtration combination centrifuge has the characteristics of first concentration and then filtration, high production efficiency, and high degree of automation. It is mainly suitable for materials with large processing capacity, low solid phase rate, and containing gum in the liquid phase. Due to its continuous filtration characteristics, high production efficiency, and continuous automatic feeding and discharging, it is particularly suitable for materials with appropriate particle sizes. Product parameters

Product structure:

Product parameters:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||